|

|

Products

Home>

Products

|

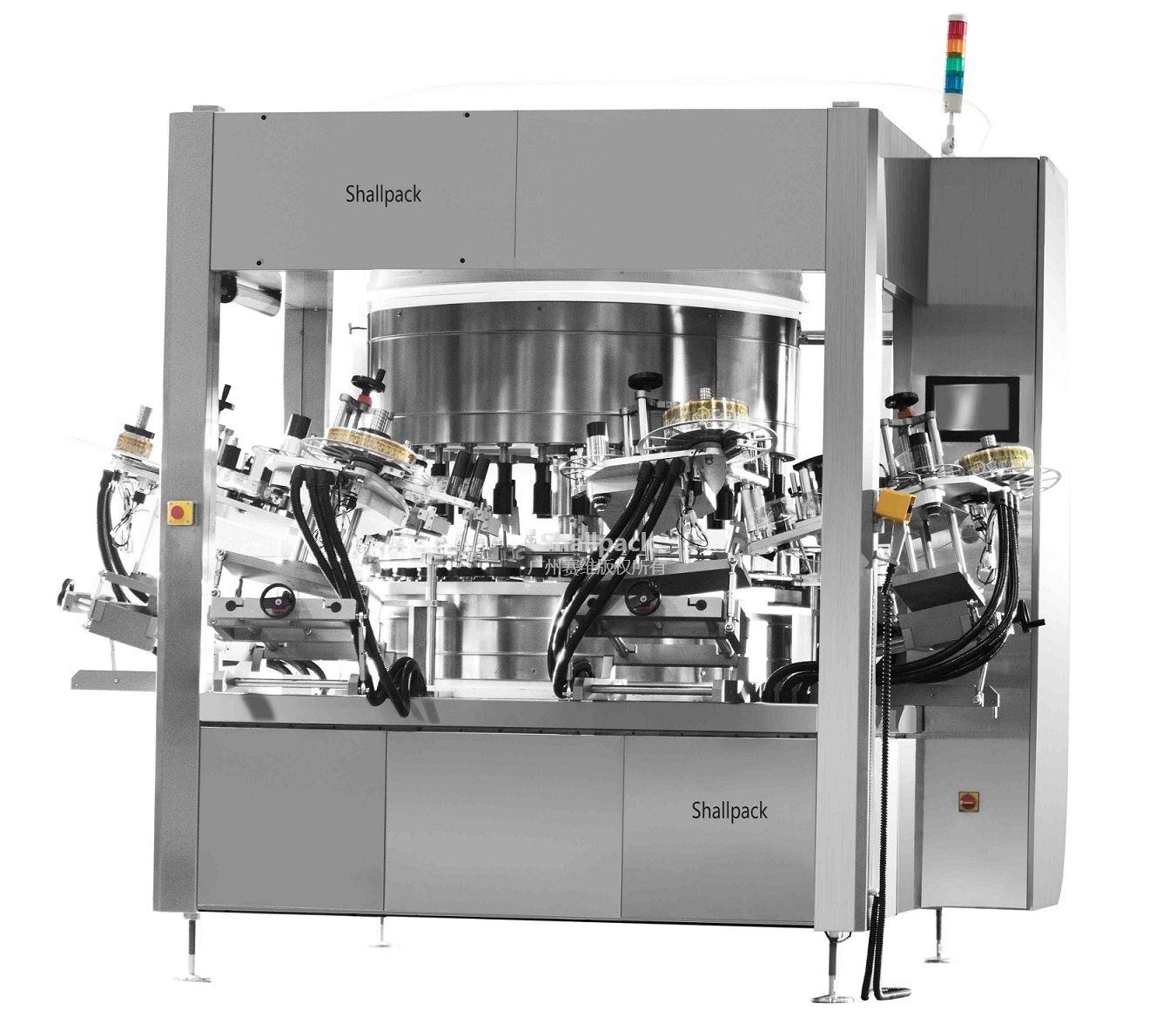

SLEP-600D Rotary position-requested labeling machine

◆ It is suitable for labeling on the outer surface of various round and square containers. According to the different models selected by the customer, one to three labels can be affixed.

◆ Stable operation speed up to 36,000 bottles/hour, stepless speed regulation, can be matched with the filling machine, greatly improving the production efficiency of the whole line.

◆This machine has obtained ten national technology patents, patent numbers: ZL201420032543.7, ZL201420032542.2, ZL201420032456.1, ZL201520500300.6, ZL201620111652.7, ZL201620110798.X, ZL201620110954.2, ZL201521036796.2, ZL201720029670.5, ZL201720323382.0.

- Features

- Technical Parameter

- Application Video

- Product Introduction

◆ Adopt smart camera, visual detection positioning and labeling method, servo motor drives the product to rotate, the camera detects the positioning point, and realizes the labeling at any designated position of the container. The positioning process is carried out during operation.

◆ The header can realize 8-dimensional space adjustment, inclination adjustment, additional position display, accurate positioning adjustment. All adjustment structures can be adjusted quickly without tools.

◆ The new tag clutch makes the tension more stable and the operation more stable. The three-point head up and down adjustment device makes the adjustment smoother and the target plate more stable.

◆ All parts are processed by numerical control, high-precision coordination to ensure the accuracy of the equipment, stable operation and low noise.

◆ All parts adopt closed design to prevent dust.

◆ The equipment is suitable for industrial production and has anti-corrosion design for all materials.

◆Professional waterproof design to ensure that all bearings operate in a dry environment.

◆ The equipment is equipped with a material flow monitoring device, and the operating speed can be automatically adjusted.

◆ The safety guard of the whole machine, open the safety door and the machine will stop automatically.

◆ All electrical controls are manufactured according to the latest CE certification.

◆ The equipment has only one independent central shaft, which is convenient for automatic lifting, no need to lock, easy to adjust, and eliminates the position change of the bottle pressing turntable and the main shaft during the secondary locking.

◆ The label delivery station and the host run linearly and synchronously, that is, the running speed of the host is automatically adjusted according to the bottle feeding speed of the previous production line, and the label delivery accuracy of the label delivery station is not affected.

◆ Open bottle pressing head design, that is, bottles can be removed manually at any station.

◆ Equipped with a bottle-in safety clutch to prevent bottle jamming.

◆ The fully waterproof bottle holder structure can be adapted to a variety of bottle types such as square bottles and special-shaped bottles and a variety of labeling processes. There is no need to replace the main parts, and the change of production is quick.

◆ All stainless steel bottle guide star wheel and hoarding, high finish, completely eliminate bottle scratches caused by friction.

◆ Clean design, convenient for cleaning and cleaning.